Polishing Diamonds in Amsterdam

By Mike Gerrard

In the world of diamonds Pauline Willemse is what you might call a rock star. As she walks out to greet me at Coster Diamonds in Amsterdam, she is leaped upon by a group of Japanese tourists who are squealing with delight and all wanting to have their photo taken with her. Pauline gives them a smile as bright as a diamond, and they go on their way as happy as can be.

Pauline Willemse has been working for Coster Diamonds for 28 years. They are the oldest diamond polishing company still in existence, founded in the Jewish Quarter of Amsterdam in 1840 by Moses Elias Coster.

‘Before World War Two,’ Pauline tells me, ‘there were thousands of polishers in Amsterdam, and today there are just three companies employing a handful of polishers each. The craft comes from India. The Dutchmen were always trading people, they went to places including South Africa, where the diamonds came from and which is still the biggest diamond producing company today. There were other polishing centres, in places such as New York and Israel, but the factories were only in Amsterdam. I also train diamond polishers. We have 7 polishers working here at the moment and I am training two more. We want to pass it on to the next generation.’

Today Pauline has the ambitious task of passing her skills on to me in just a few hours, as she also runs a Diamond Masterclass where anyone can try their hand at diamond polishing.

‘All kinds of people come on them,’ she says. ‘I’ve had professors, technicians, people whose family were diamond polishers so they wanted to try it, and people who want to go into it as a job. One man’s father had been a diamond polisher. One couple had been married ten years but still had no ring so they did a workshop together to make a diamond for their own ring.’

I’ve no such purpose, just plain old curiosity about what diamond polishing involves.

‘For the workshop it takes two hours to polish the diamond,’ Pauline tells me before we start, ‘and the whole experience takes four hours altogether. I will have done a little bit of work on getting the diamond ready, because to start from the beginning it can take several hours to polish one diamond, though it depends on the size and nature of the diamond.’

In polishing a diamond you lose 60% of the stone but a well-polished diamond doubles in value. The shavings are used to polish other diamonds, as the only thing that can cut a diamond is another diamond. Pauline sits me at the metal wheel she works at, which is covered in fine diamond dust. As it spins, the diamond will, in theory, be polished smooth, one facet at a time.

Pauline takes a diamond and places it in the metal tool that grips it tight. As a beginner I’m naturally not given a diamond as big as The Ritz to play with, but a diamond so small it would probably fit through the eye of a needle. Fortunately there’s a magnifier to allow me to look at the first face that I’ll be polishing. Unfortunately it reverses the image of the diamond and I quickly discover that being short-sighted and wearing bifocals means I won’t have a new career as a diamond polisher ahead of me.

‘Don’t worry,’ Pauline reassures me, ‘it takes six months just to learn how to use the magnifying glass properly! You get a feel for the diamond, and each diamond is different. Diamond polishing is in my body. The sound and the feel of the diamond tells me what’s happening, and then you look again, and then you polish again, always polishing and looking.’

Pauline tells me her own fascinating story while I hold the diamond against the metal wheel and inspect it periodically to see the face slowly getting smoother and shinier.

‘At the age of 14 I knew I wanted to be a diamond polisher. I have no idea where that came from, but it was in my head, I just knew it. What I liked at school was writing as small and as neatly as possible. My teacher told me it was wrong. I wasn’t very academic and they wanted me to study harder and not waste my time doing this small and neat handwriting. But I thought: watch me do something with this!’

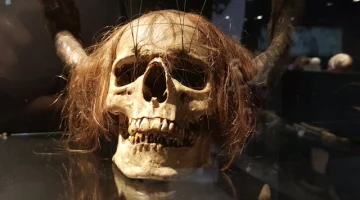

And she certainly did. In the Amsterdam Diamond Museum next door to Costers is a copy of the Dutch 1982 edition of The Guinness Book of Records. As part of the Diamond Masterclass you get a personalised tour of the museum with Pauline herself.

‘This book inspired me,’ Pauline tells me. ‘It showed in it the record holder for the world’s smallest polished diamond. One day, I thought, I’ll make one smaller than that.’

Pauline herself is now in the Guinness Book of Records for making the world’s smallest polished diamond, and a replica of her diamond is on display in the museum.

‘I’d like to go back and show the book to the teachers who made fun of my miniature writing and neatness,’ she says.

With a lot of help from the patient Pauline, I eventually end up with a diamond that she regards as acceptable. I also end up with great admiration for someone who clearly followed her dream, even if she had no idea where it came from. Today she works for eight hours at a time, and says she sometimes gets into a zen-like state of concentration that enables her to block out the visitors to the shop who stand and watch her work. Except, of course, when they want their photos taken with her.

More Information

Read about the Diamond Masterclass on the Coster website.

Photos

All photos (c) Coster Diamonds and used with permission, except photo of Mike Gerrard by Pauline Willemse and used with permission.